EPC SERVICES

Interglobal

Oil Services is a turn-key provider of pipeline integrity management

services. Our experienced staff of engineering and field service

professionals have worked with liquid and gas operators of all sizes to

ensure safe operations and regulatory compliance. We have

hands-on operations and consulting experience developing and

implementing pipeline integrity management programs.

Interglobal

Oil Services provides its customers with a variety of field

services. For turn-key projects, full construction services are

provided. Individual services we can provide include:

construction management, craft inspection (all pipeline disciplines),

pig tracking, flow measurement, anomaly ‘in-ditch’ assessment, pressure

test certification, and as-building. We perform needs assessments

with our customers in order to provide a customized solution.

Gas Compressor Station

When a gas has insufficient potential energy for its required movement, a compressor station must be used. 5 types of compressor stations are generally used. Field stations gather gas from wells in which pressure is not sufficient to produce a desired rate of flow into a transmission or distribution system. These stations handle suction pressures from below atmospheric pressure to 750 psig and volumes from a few thousands to many million cfd. Main line stations boost pressure in transmission lines. They are of generally large volume with low compression ratios. Pressure ranges from 200-1000psig.

Types of compressors:

Jet compressors:

Suction gas pressures do not vary appreciably with jet compressors.

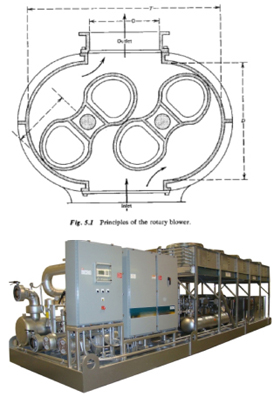

Rotary Compressor:

It is divided into rotary blower and the centrifugal compressor. Blowers are primarily used in distribution systems where pressure difference between suction and discharge is normally less than 15psi. Also used for refrigeration and closed regeneration of adsorption plants. Blower is built of a casing in which one or more impellers rotate in opposite direction.

Advantages:

• At low Horse power, large quantities of low pressure gas can be handled.

• Simple to install

• Small Initial cost

• Minimum floor space

• Low maintenance cost

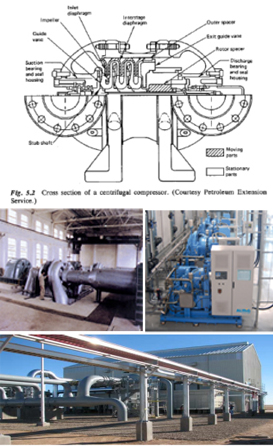

Centrifugal Compressors:

It

compresses gas using centrifugal force. Work is done on the gas by an

impeller. Gas is discharged at a high velocity into a diffuser where

the velocity is reduced and kinetic energy is converted to static

pressure.

Advantage:

• Few moving parts like impeller and shaft

• Lubricating oil consumption and maintenance costs are low

• Cooling water is normally unnecessary because of lower compression ratio

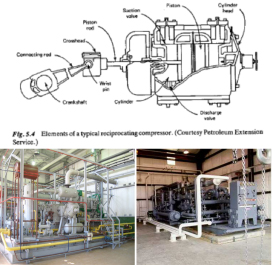

Reciprocating Compressor:

They are used in gas industry. They are built for practically all pressures and capacities. They have more moving parts; hence lower mechanical efficiencies than centrifugal machines. It has a volume up to 30000 cfm and a discharge pressure up to 10000psig.

Storage Tank Design & Execution

Interglobal Oil Services (IOS) offers the complete performance package

in dry bulk and liquid storage applications. IOS is an integrated

company that specializes in liquid and dry bulk storage applications

worldwide. Unlike tank suppliers that offer a single choice in tank

construction, IOS is a tank manufacturer that designs, fabricates and

installs all four types of steel storage tanks including Bolted RTP,

Field-weld, and Shop-weld and Hybrid Tank construction. We specialize

in integrated storage systems, prescribing the right tank design

tailored for your requirements and the unique qualities of the material

stored. IOS storage products and services not only command the highest

quality ratings in the industry, but our process operations are

vertically integrated, which promotes our global position as a

competitive price leader.

Product Offering

- Bolted RTP (rolled, tapered panel) Tanks

- Shop-Welded Tanks

- Field-Welded Tanks

- Hybrid Storage Tanks & Silos

- Aluminumdomes.com

- Integrated Storage Systems

OFFSHORE Pipeline repair and maintenance products for faster, safer, easier repairs.

For more infromation , click here for our detailed services profile.